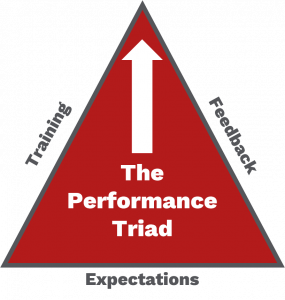

It’s important to make the most of every employee relationship and your leadership as a supervisor is critical. The three core leadership practices for supervisors are captured in the Performance Triad; these include: setting expectations, training, and performance feedback. We discussed setting expectations in an earlier post, now we turn to training.

Too often supervisors think about training the moment their new employee shows up. “Oh right, you need training, go follow that guy and do what he does.” That’s not the best approach. Effective training actually starts before a new employee even shows up for work.

Plan Your Training

Like most things in business, planning is the most important step in designing effective training. Start with the learning objectives: what will the learner know or be able to do after the training that they didn’t know or couldn’t do before? For example, suppose I’m training an employee to operate a tractor, specifically I’m training them on daily, pre-operating tractor safety and service. I’m using a standard operating procedure (SOP) much like you can find here under the heading “Check Tractor Before Operating.” My learning objectives might be something like this: “After training the learner will be able to…”

- Check tractor for visible safety hazards and maintenance needs.

- Check oil, fuel, and coolant levels and be able to add the correct fluids as needed.

- Understand the danger and consequences of operating a tractor without correct oil, coolant, or fuel.

See how that works, these objectives are all really important! The first two are about what and how to do some important tasks, the third objective gets at knowledge of the consequences if these tasks aren’t done right. Once you have clear learning objectives, it’s much easier to do the next step, plan learning activities. Let’s focus on the second objective, how will I help my new employee learn to check the oil, fuel, and coolant levels?

First gather and organize your training resources. You already have the SOP you developed for this procedure. Maybe you have an equipment manual with pictures that would also help. Or, you might find a video that explains how to check fluid levels. Once you’ve gathered resources think through each step that your employee will need to learn, notice in our learning objective 2 that they must not only check the fluids but also know what to do when they are low. That likely means a trip to the farm shop to get the right oil or coolant to add to the tractor. Or, it might mean finding the right person who can help with the important step of adding the correct fluids as needed.

Once you have your learning objectives clear, your training materials gathered, and you’ve thought through the learning process, you’re ready to put the plan together. Make a plan for the order in which you will conduct your training to help your employee learn, here’s an example plan:

Fluid Check Training Plan

- Share learning objectives and explain what we’re going to learn.

- Show employee directions found in tractor manual and video about oil checking.

- Have employee read the farm’s SOP about tractor safety and maintenance check at morning startup.

- Go to the equipment shed and show employee how to check the oil according to procedure.

- Have employee show me how to check the oil.

- Explain what to do when the oil is low, where to find the correct oil, and how much to add before checking again.

- Have employee walk through what he or she should do if the oil is low.

- Evaluate learning and answer any questions from the employee.

- Repeat training steps as needed.

- Congratulate and encourage employee for completing this part of the training.

Conduct Training

Once you’ve completed the planning steps of clarifying learning objectives, gathering training resources, and making a learning plan, you’re ready to train. Keep in mind that every person is different and we all learn in different ways and at different paces, so plan to be flexible and patient as you train. Some people learn best by hearing, others by seeing, and some must learn by doing it themselves. The plan we developed above touches on all three of these learning styles.

Set aside time when you and your employee can focus on training without interruption, let others know that you are training and should not be interrupted except for an emergency. This helps set the stage that your employee’s learning process is important. Tell your employee that he or she should ask questions at any time and that no question is a bad one. Also encourage your employee to ask questions or for help anytime after the training, it’s most important to do the job right.

Conduct the training using the Tell-Show-Do-Review method. Tell your employee how to do the task. Show them how to do the task with your own hands. Let them do the task while you watch. Review how they did by praising what they did well and correcting the parts they didn’t do correctly, repeat as needed.

Finally, take a few minutes to evaluate the overall training process to make sure the employee learned what they need and that your training was effective.

Evaluate Learning

Evaluation isn’t just for extension educators, farm trainers need to know that employees learned because sometimes it is a life and death matter! Even a simply thing like checking the oil, while not life and death, can mean the difference between finding a problem and blowing up an expensive engine!

Keep evaluation for procedure training simple and to the point. Come up with a few demonstrations or questions that your employee can show or answer to verify to you that he or she learned the most important points. For example:

- Show me where the oil level should be before you start the tractor in the morning.

- What should you do if the oil level is too low?

If your employee can demonstrate the task and answer the questions correctly, great, praise for a job well done! If not, circle back to re-train what is need and reconsider your training plan to make improvements for next time.

Follow Up

Great supervisors are constantly engaging with and coaching their employees to get better at their jobs. Farms are busy places and new employees have to learn a lot very quickly. In this environment it’s easy for an employee to forget parts of their training or to slowly drift into some bad habits. Great supervisors know this, in fact, they expect it! The solution is to follow up with employees to reinforce the training and show that correct performance matters. Follow up with employees a few days after training and a few weeks after training. Watch employees performing their new tasks, correct any problems, and offer appropriate feedback. Performance feedback is the third leadership practice in the Performance Triad and we’ll pick that up with the next post in this series.

__________________________________________________________________

By Richard Stup, Cornell University. Permission granted to repost, quote, and reprint with author attribution.

The post Optimizing Employee Performance: Part 2, Training appeared first on Cornell Agricultural Workforce Development.

Good ideas – I will pass it on to my key managers